Description

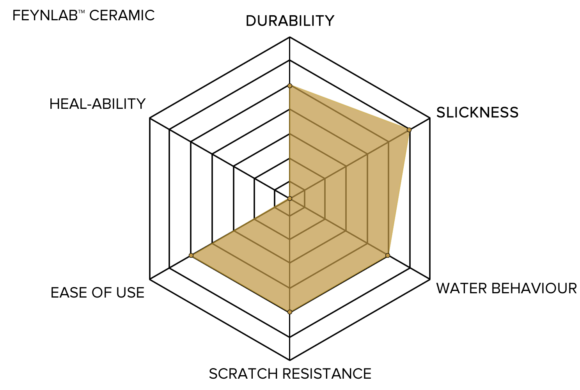

FEYNLAB® CERAMIC – engineered for extreme durability & protection for painted automotive surfaces. As an ultra-high solids coating CERAMIC adds intense gloss, U.V. & heat protection, intense chemical resistance, and increased protection from light ‘love marks’ from washing .

Typically coatings containing a high amount of solids are difficult to install. FEYNLAB engineered CERAMIC for an installer friendly experience. These combining factors make for a product that performs, lasts, and pleases vehicle owners.

Product Benefits:

FEYNLAB® CERAMIC is an economical and easy to apply high solid professional coating with a 3 year warranty. Certified installers can confidently offer CERAMIC at a competitive market price while equaling or surpassing other brands in terms of durability and performance.

High solids coatings are often tricky to apply. FEYNLAB® targeted ease of application during CERAMIC development. This innovation became one of its greatest qualities, distinguishing it from the competition. CERAMIC is exceptionally forgiving with dwell times up to 25 minutes (Times vary due to temperature and humidity).

CERAMIC has impressive properties including; excellent heat resistance, brilliant gloss, and great water sheeting ability (hydrophobicity), not to mention industry leading UV and chemical resistance.

FEYNLAB’s® true nano technology and bonding chemistry allows for an unparalleled level of protection since the formula penetrates further into the existing paint structure than anything else available.

Durability, Warranty & Approved Surfaces:

Warranty Period – 3 yrs.

Application includes 1 component layer, reaching an overall film build between 1-2 microns.

APPROVED SURFACES FOR APPLICATION ONLY: – DO NOT apply to unapproved surfaces

- Clear-coated painted surfaces (see warranty terms and conditions for approved manufacturers & vehicle types)

- Black textured plastics (test if unsure)

- Headlights & Tail-lights

- Black piano trim

- Clear-coated painted wheel rims & calipers

Shelf Life:

Unopened – 1 year.

Included:

30ml (1oz) FEYNLAB® CERAMIC (enough for 1 mid-sized vehicle)

Cautions:

Always wear respirator & gloves during application. Ensure application area is free of loose contamination.

Paint Preparation:

Thoroughly clean vehicle using FEYNLAB® PURE WASH. Follow with a topical decontamination clay treatment using FEYNLAB® PRIME. If necessary, use a ferrous iron removal product to remove all embedded iron deposits. After polishing paint to desired level, remove all polish oils using FEYNLAB® PANEL PREP to ensure optimal bonding and durability of the coating.

Directions:

Prior to application place vehicle in a well lit, temperature controlled 10°C-30°C (50°F-85°F), & contamination free environment. Have plenty (6 or more) new microfiber towels, 2 or 3 microfiber applicators on hand BEFORE application.

Once the car is prepared, it is strongly recommended to tape off and protect all unapproved surfaces. This minimizes the risk of etching by the solvents in FEYNLAB® CERAMIC on unapproved surfaces. Avoid these surfaces with CERAMIC and wipe off immediately if any product accidentally finds these surfaces.

Shake CERAMIC vigorously for 2 min before use. Open the bottle and allow the coating 1 min of air exposure.

FEYNLAB® CERAMIC Application Instructions:

- Apply enough CERAMIC to a microfiber sponge applicator to fully cover a single panel such as a door or half a hood.

- Make a “+” (plus) sign with product in the middle of the panel, then wipe around the boundaries of the section creating a frame.

- Next, fill in the framed area with slightly overlapping straight lines from left to right over the whole area and then repeat now creating up and down line. This cross-hatching ensures an level application.

- Due to its user friendliness, CERAMIC may be applied to the entire vehicle before removal.

- After application, step back and look for any areas missed or those with excess product. If found, smooth out evenly with the applicator sponge. This will ensure even drying across the panel and minimize excess product usage.

- Allow CERAMIC to dwell on the panel a minimum of 15-20 min, until it is about 75% dry. Dwell time may vary depending on humidity and temperature.

- To test removal readiness: lightly swipe a small spot with a gloved finger and looking for a clean swipe. If the swipe reveals a clean trail then remove, if the swipe smears then allow it to dwell longer. Repeat swipe test again in 2-5 min increments to determine wipe times.

- Wipe off CERAMIC following same pattern of application, using a clean microfiber towel.

Recommended Maximum Area of Application: 1/2 a vehicle. 1/3 in high humidity.

Final Inspection

Be sure to carefully inspect all finished panels for any leftover coating residue (high spots) during the final wipe. Commonly edges, emblems, and other tight areas may contain some remaining residue. High spots are much easier to remove if caught within a 20-40 min window after the final wipe, than later when the coating has set and curing has started.

Layering

Although one layer of CERAMIC is sufficient to achieve the three-year warranty on clear-coated painted surfaces, another coat may be applied to any area to gain additional thickness (such as the hood orfront bumper).

To layer CERAMIC, wait at least an hour after final wipe off of first layer. For best results and performance wait 1-3 hours between second later. Do not wait till after 3 hours as cloudiness will result.

Infrared Curing

Infrared (IR) Curing is Highly Recommended for CERAMIC.

Bake each panel with an IR lamp @ 60°C (140°F) for 15min at a distance of ~30-36″ from the panel.

Post Application Instructions

- Avoid any incidental water exposure for 24 hours. If it occurs, gently wipe water off the surface.

- Avoid all chemicals including car washes for 7 days.

- If the vehicle must be released in wet conditions before 24hrs after the final coating, then apply FEYNLAB® DETAILER after 1-2 hours of curing time.

- Wash & Maintain Paint Regularly using FEYNLAB® PURE WASH or FEYNLAB® PURE RINSELESS.

Climate Notes

All FEYNLAB® Coatings are subject to different dwell and curing time windows due to humidity and temperature. In General, the higher the humidity level the quicker the coating will cure. If humidity level approaches 75% or higher then consider lessening the recommended dwell and wipe times for the coating.

If possible apply coating in temperature controlled environment 10°C-30°C (50°F-85°F), with humidity as low as possible.